“India One” is a 1 MW electrical Solar Thermal Power Plant with 16 hrs thermal energy storage allowing for round the clock operation. This captive power plant supplies power to Brahma Kumaris headquarters in Abu Road, Rajasthan with total capacity of 25,000 people.”

Uniqueness of India One:

“India One” is a 1 MW electrical Solar Thermal Power Plant

“India One” is a 1 MW electrical Solar Thermal Power Plant with 16 hrs thermal energy storage allowing for round the clock operation. This captive power plant supplies power to Brahma Kumaris headquarters in Abu Road, Rajasthan with total capacity of 25,000 people.

India One” is a 1 MW electrical Solar Thermal Power Plant has been partly funded by Ministry for the Environment, Nature Conservation, Building and Nuclear Safety (BMUB), Government of Germany within the bilateral “ComSolar” initiative, executed for them through the German development agency, GIZ (Gesellschaft für Internationale Zusammenarbeit) and Ministry of New and Renewable Energy, Government of India under R&D Scheme.

The key features plus Research and Development achievements at India One Solar Power Plant are as follows:

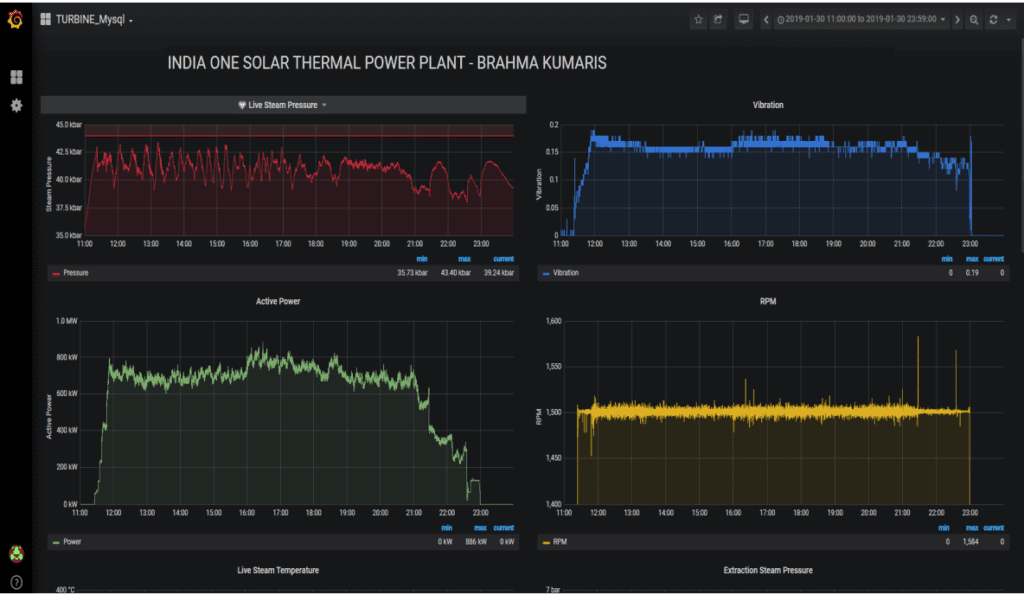

– 770 numbers of 60. square meter parabolic reflectors with unique static focus design, using special solar grade mirrors with 93% reflectivity and equipped with fully automatic dual axis tracking mechanism to adjust daily and seasonally, to the position of the Sun.

– 770 numbers of indigenously designed cast iron cavity receivers, generating directly superheated steam, up to 450 degrees Celsius temperature and 42 bar pressure. Due to the static design, receivers are cost effective and feature long lifetime with minimum required maintenance.

The 60m2 parabolic reflector by tracking the sun, concentrates the solar rays in the static cast iron receiver. Each receiver which is made out of 3 tons of cast iron acts as thermal energy storage for the night or partial cloudy condition. The cast iron core is surrounded by steam coil, which acts as steam generator by exchanging the heat from iron core to water. The high temperature steam runs through turbine connected to generator that produces electricity. “India One” is a captive, off grid power plant providing power for Shantivan complex at Abu Road.

The technology has been developed in-house and it’s a good example of “Make in India” initiative.

India One Solar Thermal Power Plant got successfully commissioned in the beginning of 2017. It is a good showcase for solar thermal power plants with storage in the world.

Newsletter

“The World Renewal Spiritual Trust (WRST) and its parent organization Brahma Kumaris have been actively involved in the research and development of alternative renewable energy concepts for more than 15 years.”

The World Renewal Spiritual Trust (WRST)

Objectives of the World Renewal Spiritual Trust (WRST) towards scientific research in solar:

- Research and Development of renewable energy devices for home, community and industrial use;

- Simplifying the design of equipment for decentralized manufacturing, enabling employment in local communities;

- Encouraging individuals and industries to use renewable energy by presenting demonstrations in all campuses of Brahmakumaris I.V.V;

- Dissemination of information on renewable energy for easy application and commercialization for home usage and industrial applications;

- Conducting trainings for participants interested in manufacturing of devices, ranging from personal use to large scale, power plant applications;

- Organizing and participating in international and national conferences on renewable energy

First time in the world:

- 60 SQM parabolic reflector designed with space frame structural engineering that gives static focus of high temperature.

- Static cast iron receiver that can be mounted on ground at a fixed location.

- The cast iron receiver that enables 24 hours heat storage capacity.

- 100% automization of the reflector for daily tracking of the sun, for seasonal tracking and for seasonal change adjustments through optical camera-based tracking mechanism.

- Direct super-heated steam generation without any heat transfer fluids (like thermic fluids, molten salt) or any heat exchangers

Demonstration of combination of Technologies:

Apart from “India One solar thermal Power plant”, at the end of 2018, Brahmakumaris have successfully Installed and commissioned “1 MW Solar Photovoltaic Plant” connected to the Grid.

This plant is commissioned through net metering scheme of state government, wherein the output of this plant is feed into the National grid which in turn gets credited in the net consumption of electrical units by the organization.

Total electrical units generated through India one:

- Avg of 3 million electrical units per year (This includes both Solar thermal and Solar Photovoltaic at India One campus)

- The solar plant is running successfully from last 4 years

- 4 years x 3 million units = Avg 12 million electrical units till date

Total savings through India One:

- On an average the net savings from India One power generation is around 150,000 USD per year

- The average savings from last 4 years is approx. 600,000 USD till date

Total carbon emission savings from India One:

- On an average the carbon emissions saving from India one power generation is around 2,550 Tons of carbon

- The average carbon emissions savings from last 4 years is approx. 10,200 Tons of carbon

“The World Renewal Spiritual Trust (WRST) and its parent organization Brahma Kumaris have been actively involved in the research and development of alternative renewable energy concepts for more than 15 years. “

Various collaborations with India One:

The World Renewal Spiritual Trust (WRST) and its parent organization Brahma Kumaris have been actively involved in the research and development of alternative renewable energy concepts for more than 15 years. Apart from being an expression of respect for the natural resources and providing sustainable energy for the BK community, it has also been an opportunity to work together with other organizations and institutes to learn and share new technologies for wider use.

Research Collaboration with various organizations and institutes:

- In 1996, R&D Demonstration with GTZ (Deutsche Gesellschaft fur Technische Zusammenarbeir GmbH – GATE (German Appropriate Technology Exchange) – Installation and Testing of Solar cooking plant for canteen Kitchens in India.

- In 1998, R&D Demonstration with MNRE (Ministry of New and Renewable Energy), GOI, “Development and demonstration of improved solar steam cooking system for 10,000 people at Abu Road

- In 2004, R&D demonstration with MNRE (Ministry of New and Renewable Energy), GOI, “Development and Testing of 16m2 Parabolic Dish with cavity Receiver for a solar steam system.

- In 2010, R&D demonstration with MNRE (Ministry of New and Renewable Energy), GOI, “Implementation of an R&D cum Demonstration project – 1 MW el. (3.5 MW) solar thermal power plant with 16 hours thermal storage for continuous operation”

- In 2011, Recognition as Scientific and Industrial Research Organization (SIRO) with Ministry of Science and Technology, GOI

- In 2014, with UNDP-GEF Concentrated Solar heating Project – Ministry of New and Renewable Energy, GOI – Development of Awareness cum Training Centre on Concentrated Solar Technologies at Brahma Kumaris, Shantivan, Abu Road

- In 2016, Research Collaboration with IISc Bangalore for “Development of High Integrated Receiver for supercritical Co2 integrated with static focus Parabolic Dish.

- In 2018, with Indian Institute of Technology, Bombay, “Design and Development of a Single Cylinder Free Piston Sterling Engine (FPSE) for net 3kW Electrical Output using Solar Energy as input”

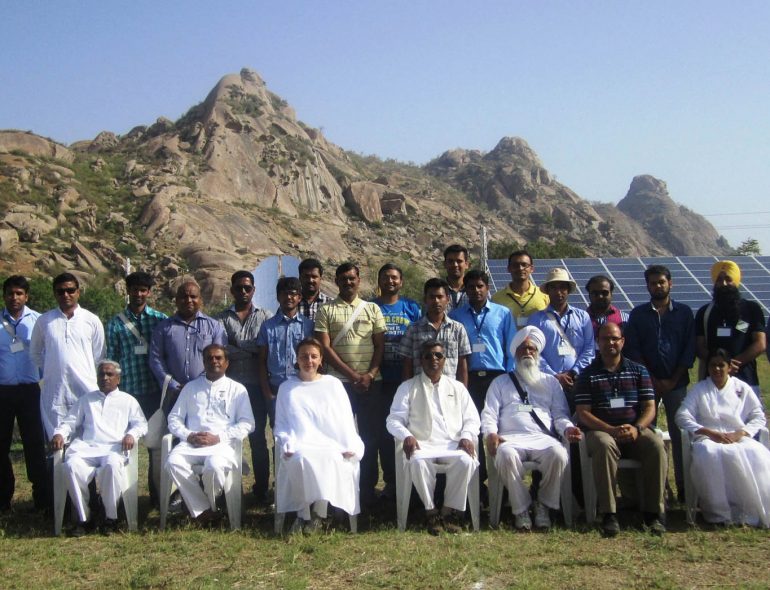

Team

“India One” team consists of about 40 engineers, scientists and support staff; competent and dedicated volunteers coordinating the project activities on the site. Being associated with Brahma Kumaris, they practice daily meditation and conscious assimilation of virtues; their professional background and dedication to spiritual life style were central to bringing this breakthrough technology to the successful implementation.

The team works in close liaison with number of engineers and manufacturers in India and abroad.

Visit at

- World Renewal Spiritual Trust India One Solar Thermal Power Plant Brahma Kumaris Shantivan Campus Abu Road – 307510, Rajasthan India

- +91 9414152925; +91 9667583989

- [email protected]